Grouser Bar Għal Bulldozer u Skavatur

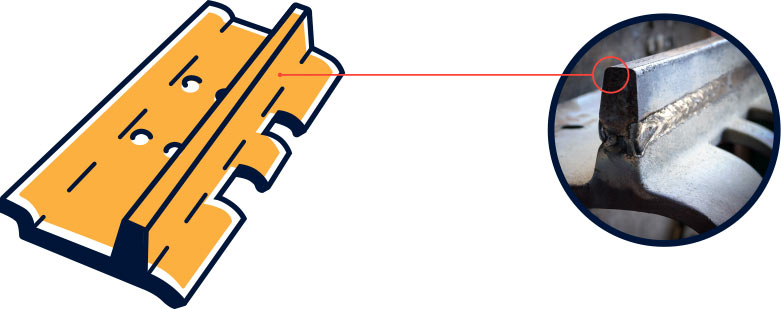

Bar tal-grouser huwa komponent tal-metall li tipikament jinstab fuq makkinarju tqil, bħal bulldozers u track loaders. Huwa mwaħħal maż-żraben tal-binarji u jgħin biex itejjeb it-trazzjoni u l-qabda billi jigdem fl-art. Il-bars tal-grouser huma essenzjali biex itejbu l-prestazzjoni tal-magna f'terren ta' sfida, bħal ħamrija maħlula jew għoljiet weqfin. Jiġu f'diversi forom u daqsijiet biex ikunu adattati għal applikazzjonijiet differenti u jistgħu jiġu sostitwiti meta jintlibsu biex tinżamm funzjonalità ottimali.

| TAQSIMA | A mm | B mm | Ċ mm | D mm | Tul (mm) | W (kg) |

| 225 | 15 | 8 | 19 | 18 | 225 | 0.51 |

| 335 | 20 | 10 | 24 | 21 | 335 | 1.13 |

| 594 | 28.5 | 12.5 | 36.5 | 64 | 594 | 9.4 |

| 610 | 7 | 5 | 22 | 40 | 610 | 2.8 |

| 910HT-558 | 28.575 | 12.7 | 38.1 | 63.5 | 558 | 9.04 |

| 911HT-558 | 26.987 | 12.7 | 41.275 | 82.55 | 558 | 11.55 |

| 911HT-610 | 26.987 | 12.7 | 41.275 | 82.55 | 610 | 12.7 |

| ACORK3 | 10.17 | 6.35 | 19.05 | 31.75 | 76.2 | 0.28 |

| D10 | 27 | 14 | 36 | 68 | 610 | 10 |

| D10-558 | 28.58 | 14.29 | 38.1 | 66.675 | 558 | 9.5 |

| D10-610 | 28.58 | 14.29 | 38.1 | 66.675 | 610 | 10.4 |

| D11 | 27 | 14 | 41 | 82.5 | 711 | 15.2 |

| D12-610 | 34.925 | 12.7 | 44.45 | 76.2 | 610 | 13.8 |

| D7-508 | 16 | 7.94 | 19 | 35.5 | 508 | 2.5 |

| D8-508 | 19.05 | 9.525 | 25.4 | 50.8 | 508 | 4.4 |

| D9-558 | 24.1 | 7.94 | 33 | 50.8 | 558 | 6.1 |

| D9-610 | 24.1 | 7.94 | 33 | 50.8 | 610 | 6.6 |

| ECORK4 | 10.17 | 7.52 | 19.41 | 38.2 | 76.2 | 0.34 |

| KCORK-4.25" | 14.3 | 9.5 | 19.1 | 31.75 | 108 | 0.44 |

| SCORK-4.25" | 25.4 | 7.9 | 28.6 | 50.8 | 108 | 1.1 |

| TCORK-4.25" | 25.4 | 6.4 | 28.6 | 38.1 | 108 | 0.84 |

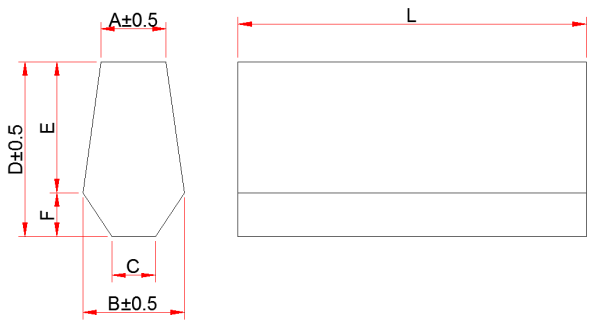

Materjal differenti għal referenza

Materjal: 65Mn Ebusija: HB300~HB320 Tul personalizzabbli, massimu 6000mm

| Numru tal-parti | A | B | C | D | E | F | L | W (KG) |

| BAR-C-3 | 14.3 | 22.2 | 9.53 | 38.11 | 28.58 | 9.53 | 76.2 | 0.405 |

| BAR-K-4 | 14.3 | 19.1 | 9.53 | 31.76 | 34.93 | 9.53 | 101.6 | 0.4075 |

| BAR-L-3 | 11.1 | 15.9 | 6.35 | 25.4 | 19.05 | 6.35 | 76.2 | 0.1974 |

| BAR-E-3 | 9.5 | 19.1 | 7.94 | 38.1 | 31.75 | 6.35 | 76.2 | 0.325 |

| BAR-A-3 | 9.5 | 15.9 | 6.35 | 34.93 | 28.58 | 6.35 | 76.2 | 0.261 |

Materjal: 40Cr Ebusija: HB500 Meħtieġ ikkastjar u trattament bis-sħana.

| Numru tal-parti | A | B | C | D | E | F | L | W (KG) |

| ECORK 3 | 9.5 | 19.1 | 7.94 | 38.15 | 31.8 | 6.35 | 76.2 | 0.326 |

| GCORK 4 | 14.3 | 25.4 | 9.53 | 44.46 | 34.93 | 9.53 | 101.6 | 0.69 |

| JCORK 4 | 19.1 | 28.6 | 9.53 | 60.3 | 49.2 | 11.1 | 101.6 | 1.11 |

| ACORK 3 | 9.5 | 15.9 | 6.35 | 31.7 | 25.4 | 6.35 | 76.2 | 0.237 |

| WCORK 2.5 | 8 | 14.3 | 6.5 | 19.1 | 13.92 | 5.18 | 63.5 | 0.105 |

| KCORK 4 | 14.3 | 19.1 | 9.53 | 31.76 | 22.23 | 9.53 | 101.6 | 0.405 |

| HCORK 4 | 15.9 | 25.4 | 9.53 | 52.39 | 41.28 | 11.11 | 101.6 | 0.835 |

| CCORK 3 | 14.3 | 22.2 | 9.52 | 38.1 | 28.58 | 9.52 | 76.2 | 0.405 |

Materjal: 42CrMoNi Ebusija: HB500-550 Meħtieġ ikkastjar u trattament bis-sħana.

| Numru tal-parti | A | B | C | D | E | F | L | W (KG) |

| D9-610 | 24.1 | 33 | 7.94 | 50.8 | 41.28 | 9.53 | 610 | 6.6 |

| D10-610 | 28.58 | 38.1 | 14.29 | 66.68 | 57.15 | 9.53 | 610 | 10.4 |

- LIEMA FORMA TAQBEL L-AKTAR MAL-MOD TA' L-ILBIES TIEGĦEK?

BARRA DRITTA

- Il-mudell tal-użu huwa uniformi tul it-triq kollha

- Iż-żarbun huwa mirqum għal wiċċ ċatt

- Jaħdem tajjeb ma' welders awtomatizzati

BARRA FORĠATA

- Disinn tond ta' lbies b'truf mikulin ħafna

- Jelimina l-ħtieġa għat-tirqim

- It-truf tal-bar huma maqtugħin f'angolu ta' 45 grad għal inqas reżistenza għad-dawrien u appoġġ miżjud

- It-truf tal-bar hooked huma ddisinjati biex jaqblu maż-żraben tal-binarji b'użu qawwi fuq it-truf

- Ideali għal żraben tal-binarji wweldjati fil-qasam

BAR MGĦAWĠA

- Disinn ta' xedd kemxejn tond

- Jelimina l-ħtieġa għat-tirqim

- Il-forma mgħawġa tal-bar tnaqqas l-ammont ta' weldjatura tal-mili meħtieġa

- Ideali għal żraben tal-binarji wweldjati fil-qasam

BAR IMŻEJJIN

- Il-mudell tal-użu huwa uniformi tul it-triq kollha

- Iż-żarbun huwa mirqum għal wiċċ ċatt

- It-truf tal-bar huma maqtugħin f'angolu ta' 45 grad għal inqas reżistenza għad-dawrien u appoġġ miżjud

- Jaħdem tajjeb ma' welders awtomatizzati